FREQUENTLY ASKED QUESTIONS

Find answers to common questions

For your added convenience, we have compiled a list of some of the most frequently asked question. Browse through this section and find our answers to these questions.

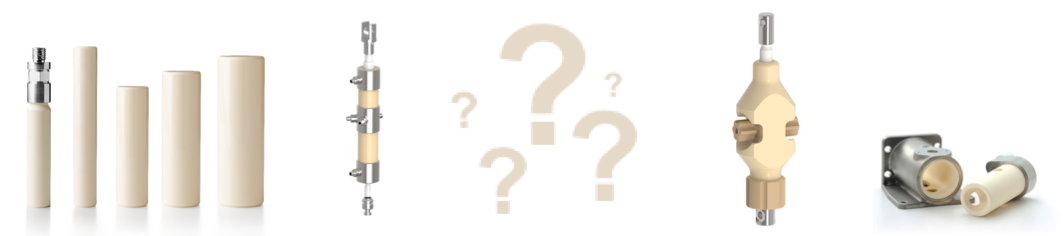

Ceramic materials are, in general, sensitive to mechanical shocks. To deal with this issue, Neoceram has developed Pharmazirc®, an exceptionally robust material for applications where fragility can be a problem. In addition, the Neoceram engineering department possesses all the necessary knowledge of the process and understanding of the materials to minimize the fragility of the finished product through the choice of the best design and protections.

Our raw materials are very fine grain powders selected from the most stringent specifications available on the market. The powders are blended with proprietary additives and formed into billets, using extreme pressures from an isostatic press. The billets are then fired, over a carefully controlled time/temperature cycle, to reach the desired mechanical properties. The shaped items are then fine ground, assembled with the stainless steel components and mated. Our product quality control includes functional and leak tests.

• Pharmalox® and Pharmazirc® both have extremely high resistance to wear and corrosion characterised by their superior hardness and lack of porosity.

• Our pumps release much less particles than other materials normally used for filling applications, whatever the filled product.

• Pharmalox® and Pharmazirc® enable much improved filling accuracy over time due to the fact that, in conjunction with their stability, they can be machined to very fine precision.

• Ideal for use in CIP/SIP conditions due to their low coefficient of expansion.

We have developed fine machining tools to obtain perfect geometry and surface finish on both ceramic and steel in order to ensure a fit that is adapted to every application.

Yes, because of their low friction coefficient, ceramic pumps can run dry without seizing up.

Yes. Nevertheless, the T° of use should be communicated to our sales representative prior to ordering the pumps, to allow the definition of the best option for material selection and clearance.

Yes, ceramic pumps can be autoclaved. We recommend that they be disassembled prior to autoclaving.

Pharmalox® and Pharmazirc® are chemically inert, their fine grain allows for a much smoother surface finish than standard GMPs. Ceramic samples are available upon request.

Yes, our pumps are designed to be interchangeable with stainless steel pumps without any machine modification.

Our pumps can run with most suspensions and crystallizing products. Nevertheless, we advise the customer to send us a sample of their product, with the specification of the filling parameters, so that we can perform in-house tests and custom design the best possible solution.

Yes, a male or female part can be repaired/replaced, but will have to be mated again to the piston or to the housing of the original pump.

Ceramic pumps can be cleaned as any other pump with WFI and any other detergent (basic or acid) that is available on the market. Ceramic pumps can also be cleaned in an ultrasonic bath. Usually they do not require any change or amendment of existing cleaning procedures.

As with any other high precision product, ceramic pumps should be handled with care. Light shocks during cleaning and/or autoclaving will not damage them nor cause seizure during production. Heavy duty trays that hold the pumps, minimizing handling during cleaning and autoclaving, can be purchased. A user manual detailing pump assembly, handling instructions, cleaning procedures, conditions of use and trouble shooting is provided.

NEED SOME HELP? WE’RE HERE FOR YOU

Neoceram is renowned for the quality of its products but also for its services.