Neoceram’s patents formalize core technological principles developed through long-term research into ceramic materials, component interfaces, and system behavior under critical process conditions. They define protected design principles and constraints that support the engineering of precision components and systems.

While certain patents may be reflected in specific product implementations, their scope extends beyond individual configurations, defining how technologies are applied, adapted, and combined across different solutions and application requirements. This patent-driven approach ensures continuity between research, development, and implementation while maintaining flexibility across industries and regulatory environments.

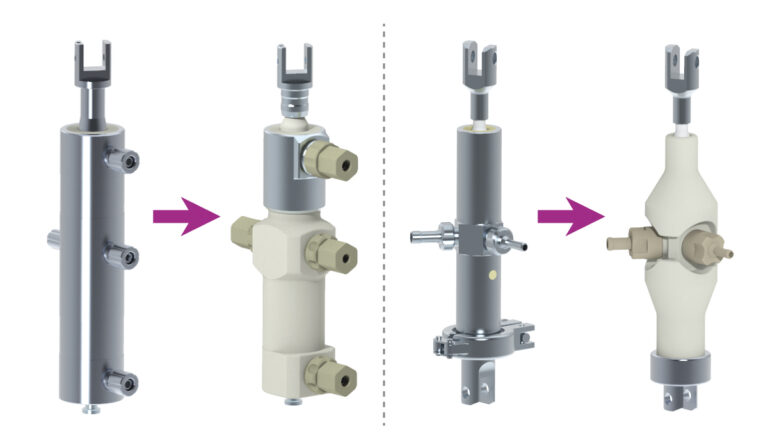

The NAKED® design concept originates from Neoceram’s research into minimising material interfaces in contact with process fluids.

By reducing metallic components and optimizing ceramic-to-ceramic connections, this approach addresses critical challenges related to cleanability, contamination risk, and long-term process stability.

Research focused on material behaviour, sealing geometry, and surface interaction led to a design logic where the ceramic component becomes the primary functional element, rather than a coating or insert. This concept forms the technical basis for solutions developed for applications requiring high purity, repeatability, and compliance with stringent pharmaceutical standards.

Image: Ceramic connection geometries studied during the development of the NAKED® design concept.

Easy Fitting® is the result of Neoceram’s research into system architecture and operator interaction during installation, maintenance, and cleaning processes.

The objective of this research was to reduce handling complexity while preserving precision, alignment, and hygienic integrity.

By analysing interfaces between components, tools, and operators, Neoceram developed an architectural approach that simplifies assembly and disassembly without introducing additional contamination risks.

This research-driven system logic supports faster changeovers, improved ergonomics, and consistent performance across filling and dosing environments.

Image: System architecture developed to study installation logic, component alignment, and handling ergonomics.

Neoceram’s Single Use® system logic was developed through research into process flexibility, sterility assurance, and material compatibility in disposable environments.

The focus was not on individual components, but on how ceramic technology can be integrated into single-use workflows without compromising precision or reliability.

Research addressed issues such as material stability, interface consistency, and performance repeatability across batches.

This system logic enables the application of ceramic-based dosing principles in contexts where disposability, rapid changeover, and contamination control are essential.

Image: System-level studies supporting the integration of ceramic components into single-use environments.

Best-in-class service and care is our passion