Customized Solutions address specific machine, process, and operational constraints that cannot be resolved through standardized upgrades alone.

Developed in close collaboration with customers, these solutions adapt Neoceram’s engineering capabilities to existing equipment, production layouts, and performance targets, ensuring compatibility, reliability, and long-term operability within real manufacturing environment

BENEFITS

Our patented monolithic ceramic dosing pumps are machined from a single block of ceramic with no coatings and just one product-contact material. The Naked® line features built-in inlet/outlet and a compact, solid design that protects hose connections within the ceramic body.

With a seal-less construction and reduced number of components, it ensures easier maintenance, minimized risk, and seamless integration into your existing machines. Cylinders and pistons are entirely ceramic, while connection parts use stainless steel and PEEK where needed — ideal for pharmaceutical environments requiring precision and sterility.

Best-in-class service and care is our passion

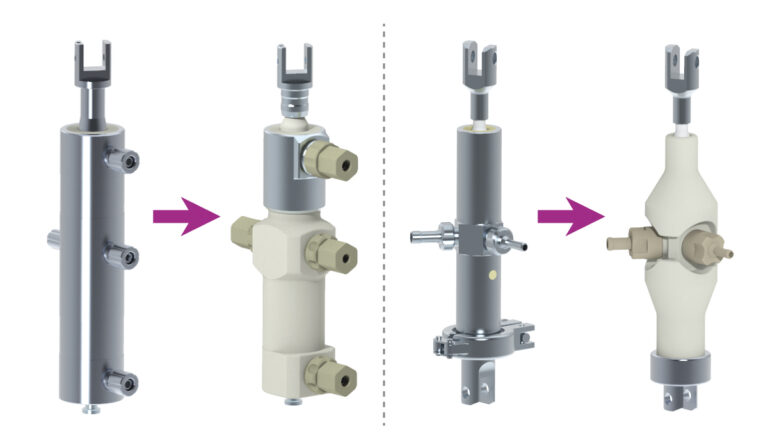

Neoceram Pumps: Fully Interchangeable Male Components

The X-change® system ensures dimensional precision in machining pistons, valves, and cylinders, making male components fully interchangeable—not just within the same batch, but also across batches with identical clearance.

With 20+ years in the pharmaceutical industry, Neoceram identified matching errors as a major cause of leakage, seizing, and pump jamming.

With X-change®, pistons and cylinders are exactly the same size, eliminating seizing risks. If a piston breaks, a single spare fits all cylinders, reducing stock and costs

BENEFITS

BENEFITS

Combines single-use convenience with ceramic pump performance

Designed for sterile environments and isolators

Supports volume ranges from 0.8 to 8 ml

Flexible installation: stand-alone, integrated, or EOM

Compliant with CFR21P11 and batch reporting requirements

Ideal for biologics, cell and gene therapy applications

Enables rapid product development and filling of complex products

Reduces contamination risk with disposable components

Neoceram introduces the Precyx® Single Use Filling Unit, a high-performing solution that combines the convenience of single-use technology with the stable, accurate, and reliable performance of a ceramic pump.

Designed for sterile environments and compatible with isolators, Precyx® is available as a complete filling kit, including a single-use ceramic pump and an active distribution device. It can be installed as a stand-alone machine, integrated into existing systems, or connected to existing motors (EOM).

Precyx® addresses the growing demand for flexibility and speed in the pharmaceutical industry, driven by the rise of biologics, cell and gene therapies, and the need for rapid R&D and product development. It meets key market requirements by enabling the quick filling of complex products and supporting fast innovation cycles.