Neoceram trademarks identify proprietary developments in advanced ceramic materials as well as in system architectures and functional design logics derived from research and engineering activity. They designate branded areas of technical development associated with specific material behaviors, interface characteristics, and performance conditions.

Neoceram trademarks provide a consistent technical reference for how these material and system innovations are applied within different solutions, according to process requirements, regulatory context, and configuration needs.

Together, they connect material research and system innovation to engineered performance across the Neoceram portfolio.

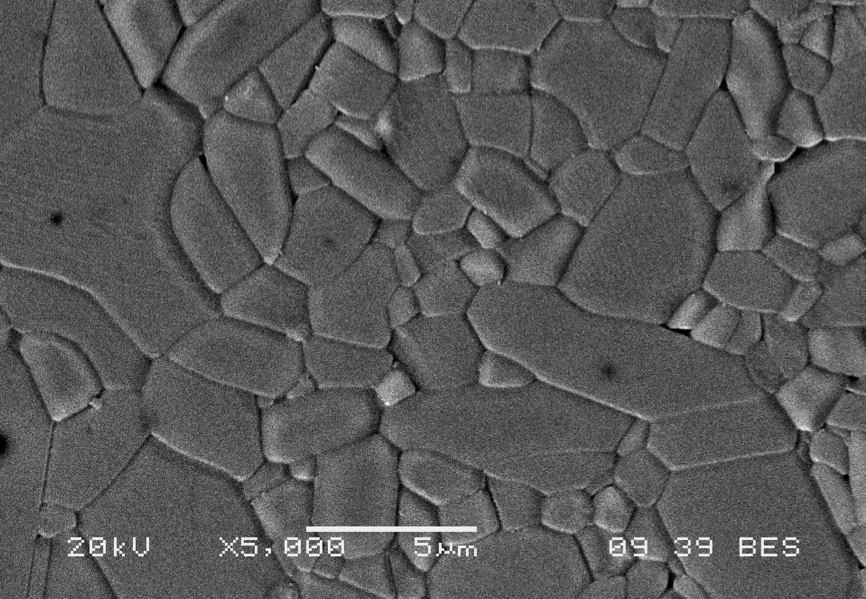

Pharmalox® is a high purity alumina ceramic (>99.7% Al2O3) specially designed for our products.

The high purity of this material results in very clean grain boundaries which contribute to its excellent corrosion resistance in the presence of both acid and alkali-based cleaning solutions e.g. NaOH and HCl.

Pharmalox® is inert, non-cytotoxic and does not release particles. It is easy to clean due to the low porosity. It has high wear resistance, a low friction coefficient and accepts very smooth surface finishes.

Pharmalox® complies with directive 80/500/EEC amended and FDA regulation

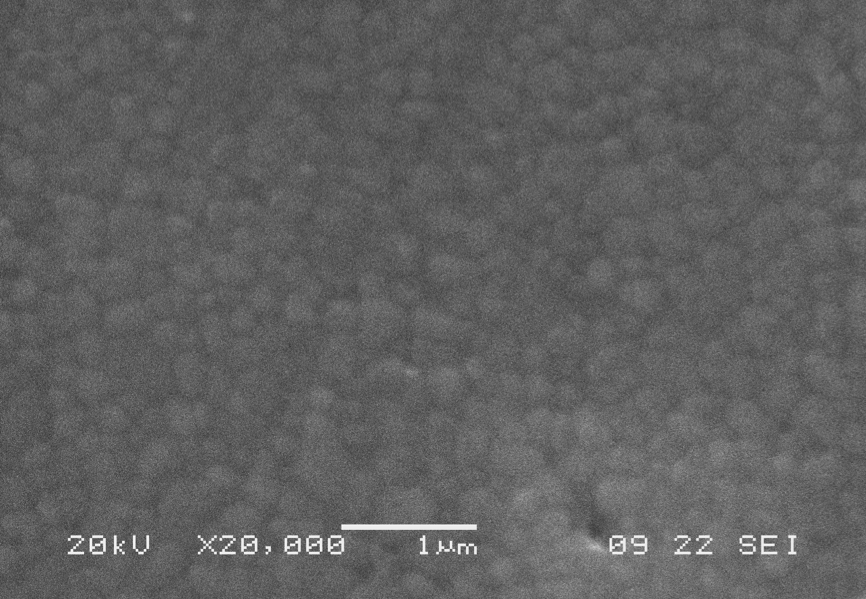

Pharmazirc® is a Yttria partially-stabilized zirconia ceramic specially designed for our products.

Its carefully controlled chemistry and microstructure imparts excellent resistance to corrosion by both acid and alkali cleaning solutions and to the hydro-thermal destabilization that happens with other zirconia ceramics during steam sterilization.

This material is also non-cytotoxic and does not release particles. It is easy to clean due to the low porosity. It has high wear resistance, a low friction coefficient and accepts highly smooth surface finishing as a result of its very fine grain size and low porosity.

Pharmazirc® complies with Directive 80/500/EEC amended and FDA regulation

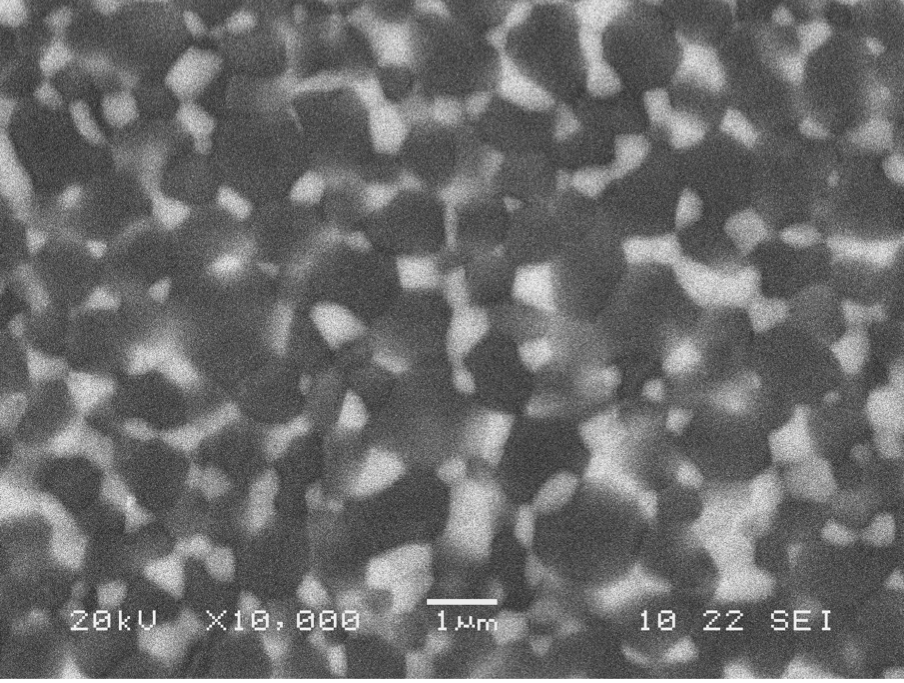

Thermazyl® is a zirconia toughened alumina ceramic specially designed for our products.

Its carefully controlled chemistry and microstructure imparts excellent resistance to corrosion by both acid and alkali cleaning solutions and to the hydro-thermal destabilization that happens with zirconia ceramics during steam sterilization. This material has been especially designed for application requiring good thermal shock resistance.

This material is also non-cytotoxic and does not release particles. It is easy to clean due to the low porosity. It has high wear resistance, a low friction coefficient and accepts highly smooth surface finishing as a result of its very fine grain size and low porosity.

Thermazyl® is X-Ray detectable (smallest detectable size as low as 0,8 mm) and complies with Directive 80/500/EEC amended and FDA regulation

Interchangeability principle derived from interface geometry and tolerance studies in ceramic assemblies.

X-CHANGE® originates from Neoceram’s research into dimensional consistency, wear management, and interface stability in ceramic component assemblies.

The principle addresses how critical elements can be replaced or reconfigured while preserving system alignment, performance repeatability, and process integrity.

Research focused on interface geometry, tolerance control, and material behavior under operating conditions led to an interchangeability logic that supports controlled maintenance and long-term system evolution. This principle enables flexibility at component level without introducing variability at system level.

X-CHANGE® is applied where predictable replacement strategies and consistency over time are required, particularly in environments subject to wear, frequent servicing, or stringent validation constraints

We customize products and solutions to deliver precision, reliability, consistency and innovative design