How a customised Neoceram solution solved serious problems with the dosing of viscous products.

COMPANY PROFILE : Our customer is a French ‘blue chip’ company having long established operational excellence in the production of high end lipsticks and other cosmetics. Servicing the global market, they produce luxury cosmetics in the complete range of skincare and makeup.

Looking to improve the dosing of high temperature viscous products.

CONTEXT : Experiencing leaking and seizing problems in its lipstick production, our customer was looking for an new and improved dosing system. To that end they asked Neoceram to develop an innovative solution.

Product leakage and/or seizing of the dosing components.

CHALLENGE : Dosing at elevated temperatures can create product leakage and seizing of the dosing components. This was the problem our customer was facing. Due to the high temperatures, conventional dosing systems start leaking and/or seizing. Therefore, they were looking for an integrally heated dosing system having the advantage of highly accurate, high temperature filling of lipsticks without the risk of seizing.

A dosing block consisting of solid ceramic components.

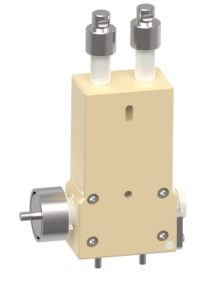

SOLUTION : Giving due consideration to the high viscosity and abrasive properties of the products, we engineered and developed a fully ceramic dosing block which, when operating within the required specification, gives results that exceed expectations.

SOLUTION : Giving due consideration to the high viscosity and abrasive properties of the products, we engineered and developed a fully ceramic dosing block which, when operating within the required specification, gives results that exceed expectations.

RESULT : Our dosing block is dosing a homogeneous, heated product with high accuracy and minimal maintenance. No leakage has been observed since the start of production.

NEED SOME HELP? WE’RE HERE FOR YOU

Neoceram is renowned for the quality of its products but also for its services.