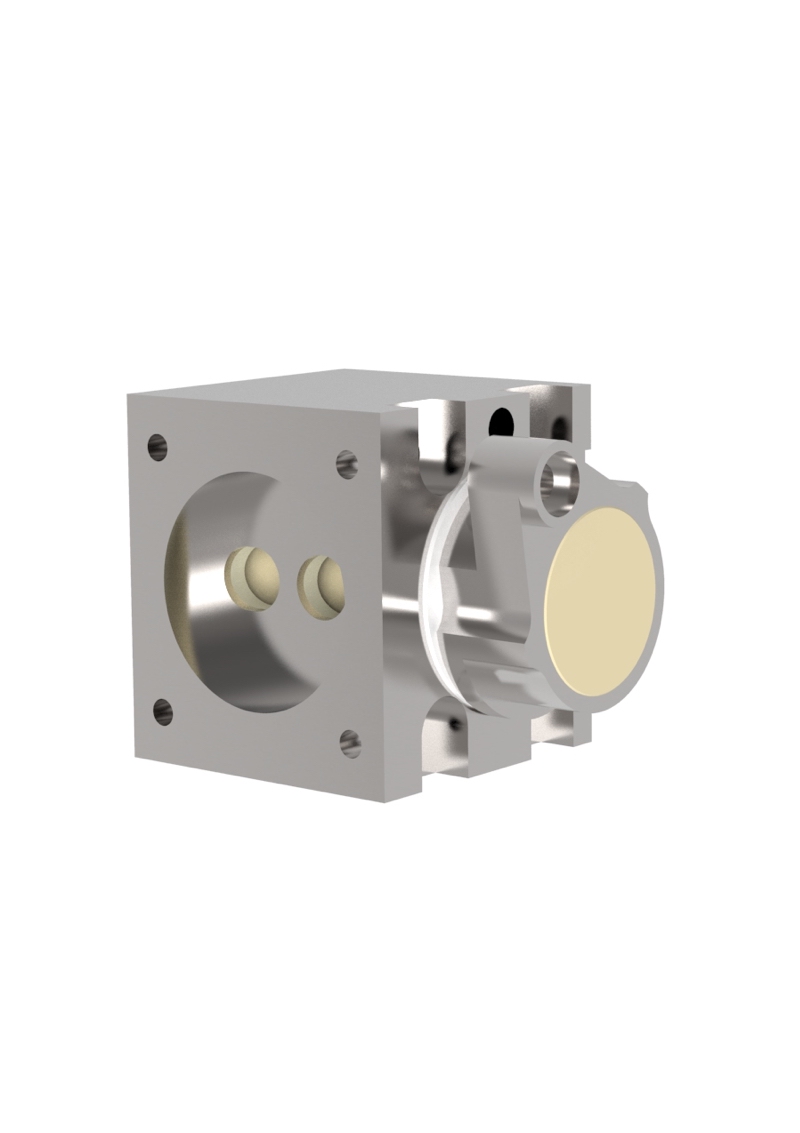

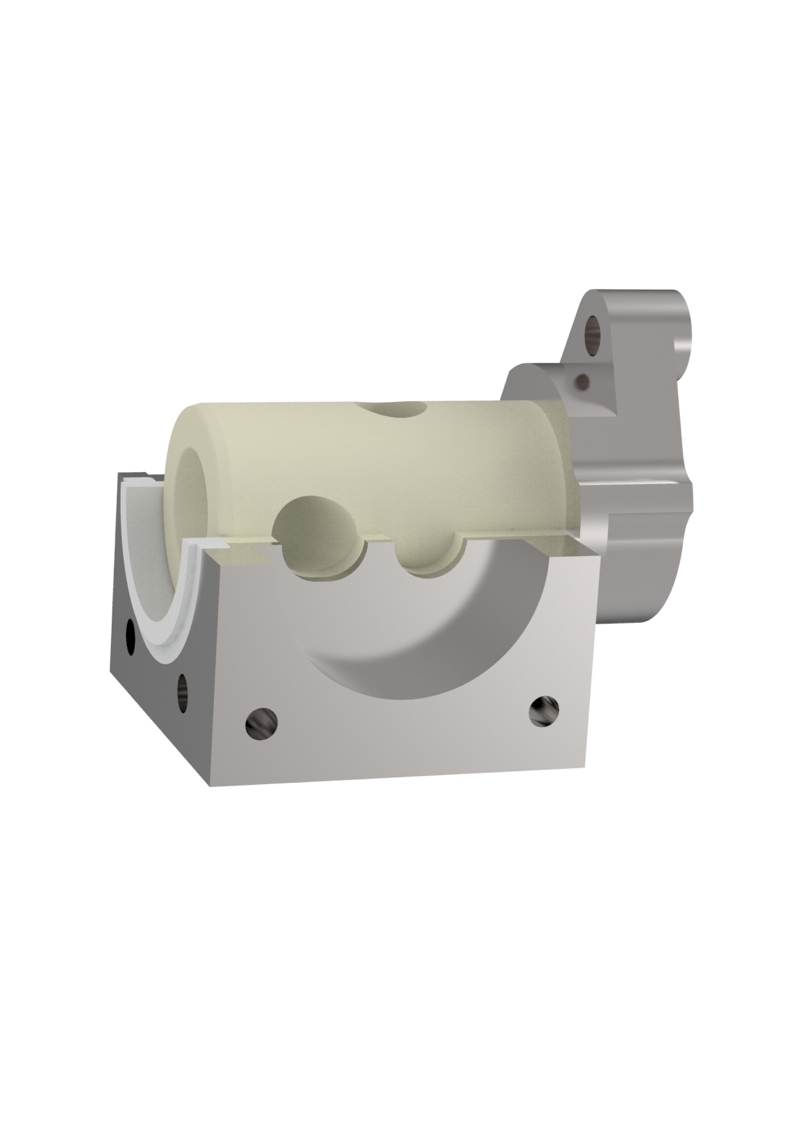

Neoceram rotary valves have a solid monolithic ceramic ‘plug’which when rotated controls flow by opening and closing the inlet and outlet ports in an equally substantial ceramic sleeve.

Being much harder than alternative materials such as steel or Peek the ceramic rotary valves made by Neoceram resist wear and therefore have a much longer life. Particularly suitable for products containing fibres, seeds and other particulates, the rotary valves provide accurate non-drip dosing.

Able to run dry the robust seal free precision valve is also resistant to thermal shock.

Neoceram rotary valves can be supplied in either 2 or 3 way action and may be custom designed or manufactured to suit one of the main machine brands.

APPLICATIONS:

|

|

|

|

High-tech ceramics

- Proprietary ceramics

- X-Ray detectable

- Thermal shock resistant

- Complies with:

- Directive 80/500/EEC amended

- FDA registration

Effective dosage for difficult products

- Non dripping

- Ideal for fibrous and seed containing food

- Non seizing

- High accuracy

No contamination

- No coating—monolithic ceramic

- High corrosion resistance

- No lubrication required (able to run dry)

Hygienic design

- No sharp edges that can easily break

- Much harder than steel and Peek

- High wear resistance

- Long lifespan

- Resistance against: sugar, salt, stones, seeds, chemicals, cleaning agents…

All our valves are PLUG and PLAY

NEED SOME HELP? WE’RE HERE FOR YOU

Neoceram is renowned for the quality of its products but also for its services.