THERMAZYL®

Its carefully controlled chemistry and microstructure imparts excellent resistance to corrosion by both acid and alkali cleaning solutions and to the hydro-thermal destabilization that happens with zirconia ceramics during steam sterilization. This material has been especially designed for application requiring good thermal shock resistance.

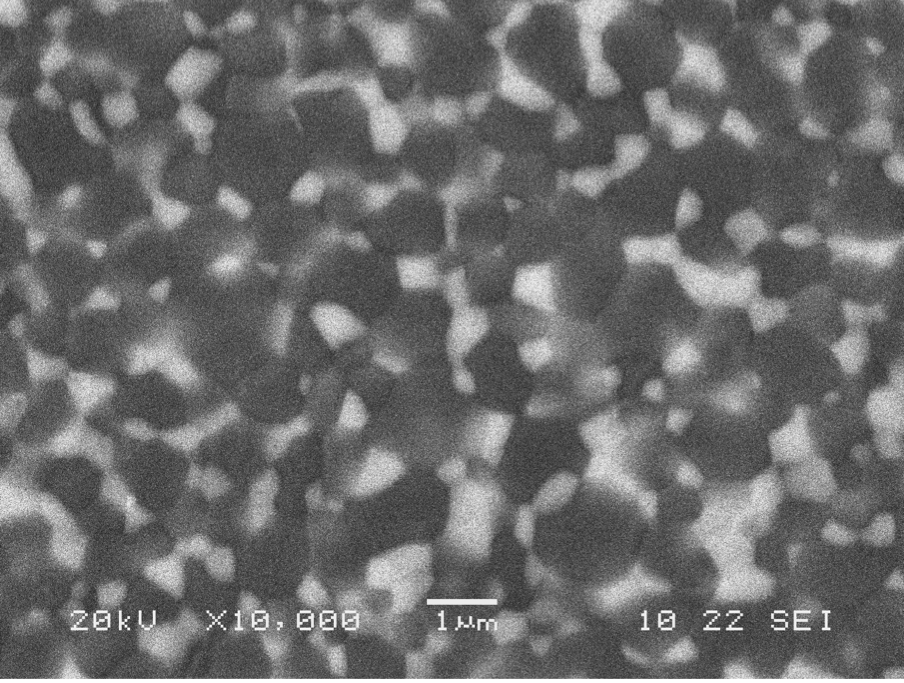

This material is also non-cytotoxic and does not release particles. It is easy to clean due to the low porosity. It has high wear resistance, a low friction coefficient and accepts highly smooth surface finishing as a result of its very fine grain size and low porosity.

Thermazyl® is X-Ray detectable (smallest detectable size as low as 0,8 mm).

Mechanical, physical and electrical properties

Values at 20°C

| Properties | Unit | Thermazyl® |

|---|---|---|

| Color | / | White |

| Density | 103 kg/m3 | > 4.3 |

| Porosity | % volume | 0 |

| Thermal expansion coefficient (20 – 1000°C) | 10-6 /°C | 9 – 9.5 |

| Thermal conductivity | W/m.°C | 20 |

| Vickers hardness | GPa | 16 |

| Bend strength | MPa | 600 – 700 |

| Young’s Modulus | GPa | 350 |

| Fracture toughness (K1C factor) | MPa.m1/2 | 5 – 6.5 |

The properties quoted above are typical and should be used for guidance only. They vary somewhat with method of manufacture, size and shape and advice should be sought for critical applications.

Food and pharmaceutical products contact

Thermazyl® complies with :- Directive 80/500/EEC amended

- FDA regulation

NEED SOME HELP? WE’RE HERE FOR YOU

Neoceram is renowned for the quality of its products but also for its services.