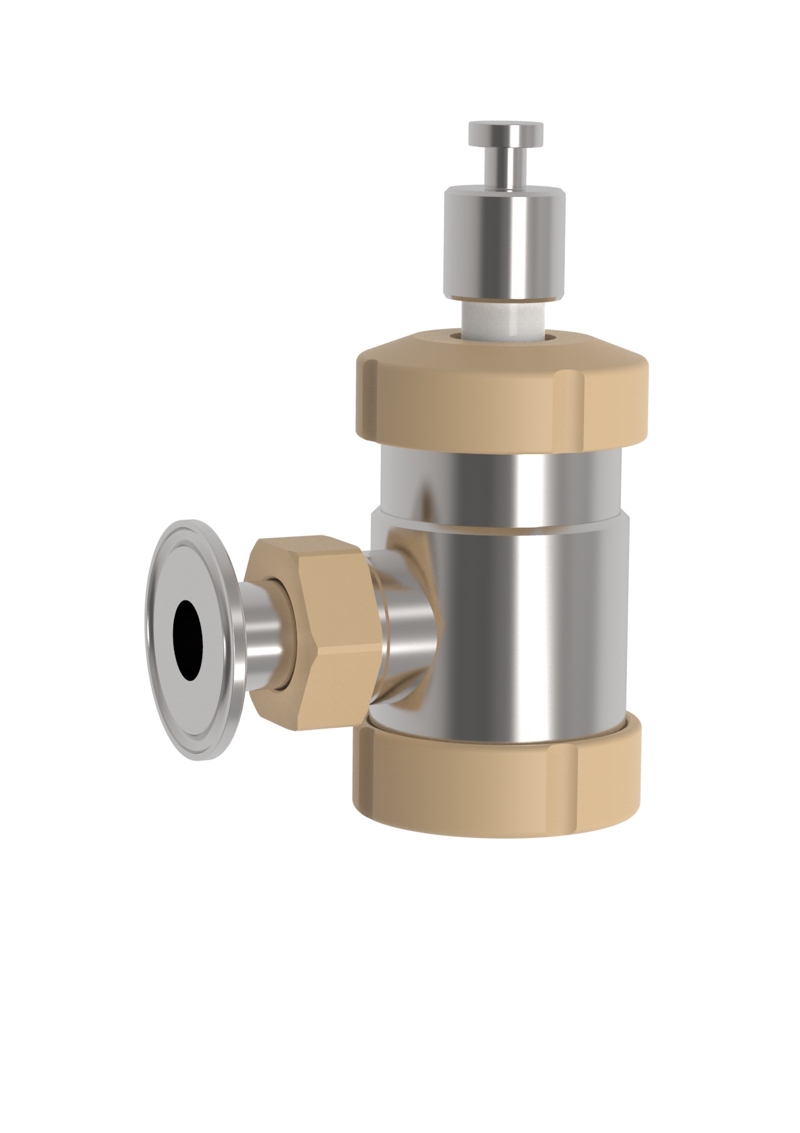

Utilising high tech ceramics, Neoceram plunger valves offer effective dosing solutions for all types of products no matter how difficult they may be to fill.

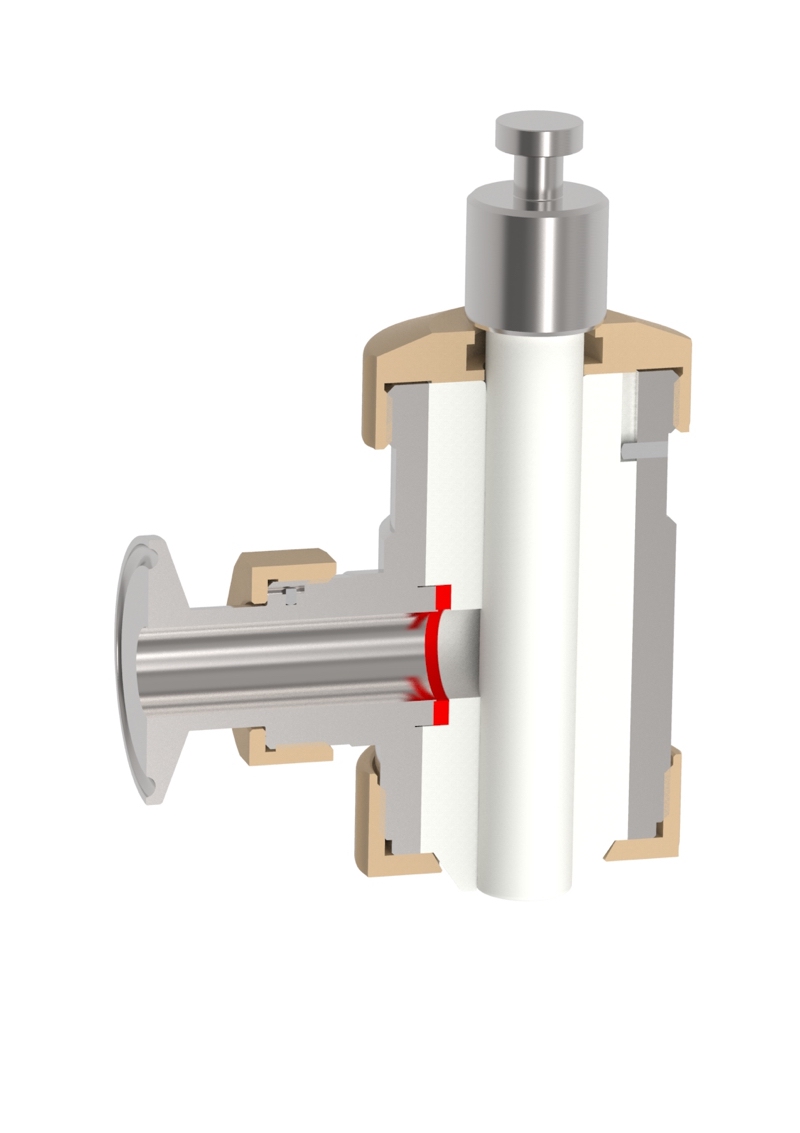

Our plunger valves control product flow by the opening and closing action of a ceramic ‘plunger’ in a ceramic sleeve. Precision manufacturing combined with high tech ceramics enables tight tolerances which require no seals and provide drip-free dosing.

Custom designed to meet all appropriate hygiene standards, Neoceram plunger valves come in non-CIP, CIP/SIP or aseptic format*. Adaptable to most machines, our valves will optimise your filling performance whilst significantly reducing maintenance costs.

*using a steam barrier

APPLICATIONS

|

|

|

|

High-tech ceramics

| Proprietary ceramics |

| X-Ray detectable |

| Complies with: |

| Directive 80/500/EEC amended |

| FDA registration |

Advantages

| Effective Dosage for difficult products |

| No seals |

| Superior process for fibrous food |

| Clean cutting of pieces |

| NON DRIPPING (correct lid sealing) |

| NON SPLASHING |

| NON SEIZING du to solid inclusions |

Hygienic design

| CIP design available |

| Aseptic applications (steam, air barriers) |

| Excellent cleanability, zero porosity |

| EHEDG design |

All our valves are PLUG and PLAY

NEED SOME HELP? WE’RE HERE FOR YOU

Neoceram is renowned for the quality of its products but also for its services.