A new generation of pumps

A new generation of pumps for sterile filling

The “Naked” design is an exclusive innovation which brings together the features of the standard ceramic pump design with the advantages of a patented solution.

Advantages of classic design:

Superior wear/corrosion resistance

No coating

FDA approved materials

Zero porosity

Ultra LOW Ra/friction coefficient

Low thermal expansion

Dry run possible (no need for lubricants to start)

Additional advantages of naked pump:

Cylinder and connections are machines in one solid piece of ceramic (monoblock)

Only ceramic in contact with the dosed product

Conical (seal-less) ceramic plug

Fully compatible with existing fillers

Characteristics of Naked ceramic pumps

The naked pump version combines outstanding design with superior performance

Outstanding design:

Very compact and solid

Built-in ceramic connections protected by recess in machined in the ceramic pump body

In line with recent FDA and CGMPs guidelines (fewer components)

Lighter than stainless steel version (for large volumes)

Fully compatible with existing machines

Superior performance:

Only one material (ceramic) in contact with product

Improved cleanability

Suitable for metal sensitive products

Perfect stability over time and repeated autoclaving

Main features

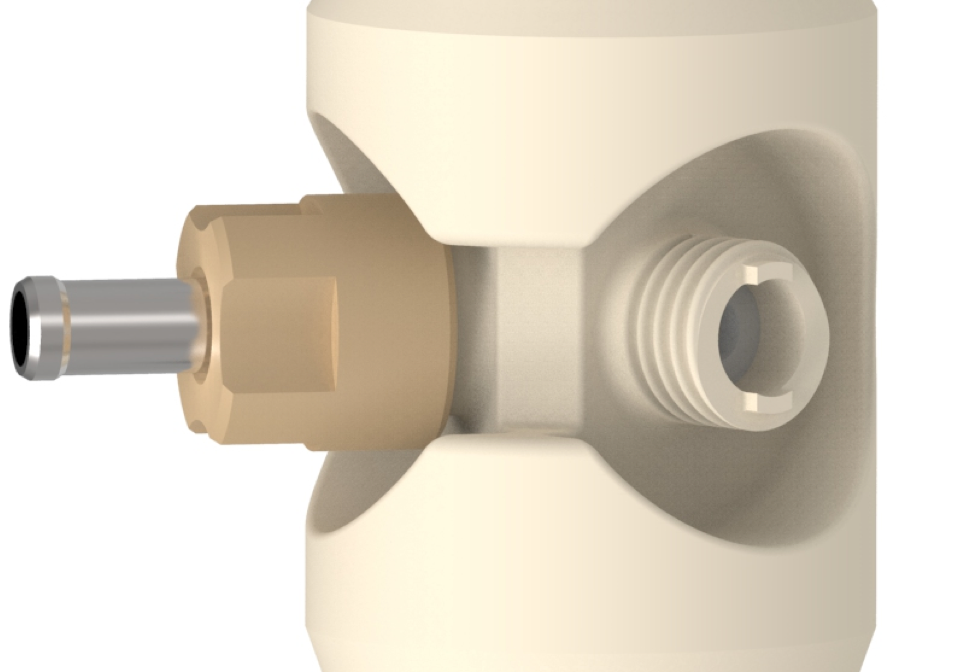

In/out ports

In/out ports

Thread machined in the ceramic pump body

Recess built in the body of the cylinder to protect inlet/outlet connection from shocks during handling

Recess designed to be easily cleaned

In/out lets with Peek nuts (to avoid steel marks on ceramic and nut seizures)

Customized thread profile

The cylinder is built in one solid piece of ceramic. There are no stresses applied on the ceramic body by thermal expansion of stainless steel case thus very stable pump geometry over time and after repeated autoclaving. Also, pump weight are reduced (the weight difference is greater for larger volumes: up to 1kg less).

Seal less conic plugThe cylinder has a liquid tight ceramic bottom plug (no gasket required). The parts are sealant thanks to the accurate lapping and metrology of the conical surfaces and the slight pressure applied via the peek nut. This solution has been chosen because it guarantees the best and easiest cleanability, is suitable for all products (including metal sensitive ones).

As an additional feature, Neoceram is developing interchangeable ceramic plugs to facilitate assembling and repairing.

Improved cleanabilityNaked pump absorption of hydrogen peroxide is comparable to the one of traditional ceramic pumps. There is no influence on the H2O2 releasing time. Such pumps are suitable for Ultrasonic bath cleaning.

All the surfaces in contact with the product to be dosed can be polished up to very low roughness (upon request): the Ra can be lesser than 0.1 microns on Pharmazirc® surfaces and lesser than 0.3 microns on Pharmalox® surfaces.

Benefits of Naked ceramic pumps

Patented solution (with conic plugs and Peek nuts)

innovative hygienic design (fewer components)

Plug & Play solution with existing standard pumps

Possible revamping of old machines

True no metal contact solution given as standard

Neoceram at a glance

Since its foundation in 1985, Neoceram has specialised in the development and production of ceramic solutions for demanding applications. The company, that relies on advanced technology and excellence, is now the market leader in the development and manufacturing of ceramic precision dosage solutions (pumps, valves and filing systems) for the optimisation of fluid treatment in pharmaceutical, cosmetic and food applications. Neoceram has more than 20 ans years expertise in sterile applications and is ISO 9001 qualified since 1998.

Communication Team

Communication Team

+32 64 671 450

info@neoceram.com